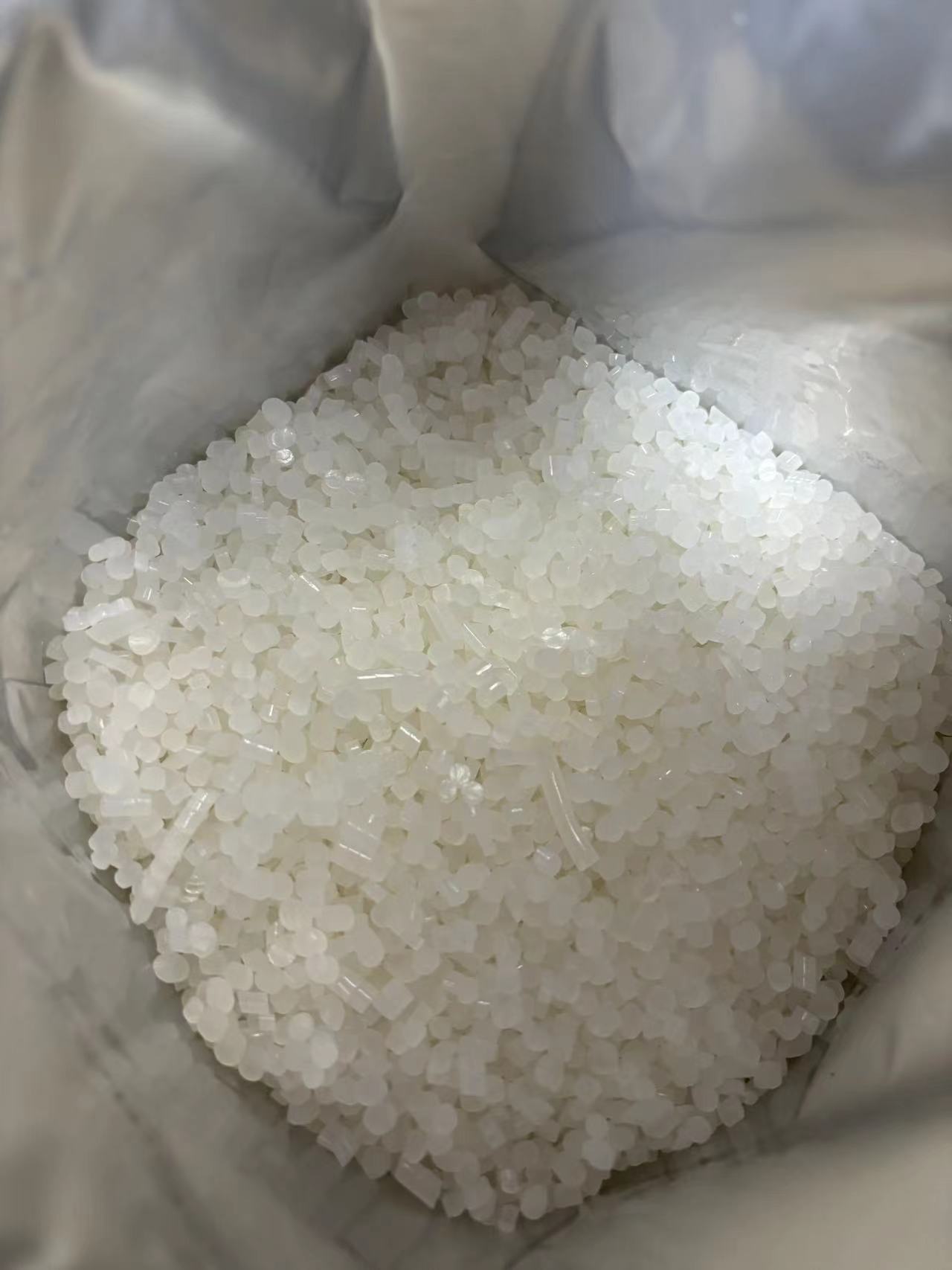

I-TPU/i-granule yepulasitiki/i-TPU resin ephinde yasetshenziswa kabusha ngekhabhoni ephansi

Mayelana ne-TPU

I-TPU ephinde yasetshenziswaineziningiizinzuzo kanje:

1.Ubungane Bemvelo: I-TPU ephinde yasetshenziswa yenziwe ngezinto eziphinde zasetshenziswa, okusiza ekunciphiseni imfucuza kanye nokusetshenziswa kwezinsizakusebenza ezingakasetshenziswa. Inegalelo endaweni ezinzile ngokuphambukisa imfucuza ye-TPU ezindaweni zokulahla udoti kanye nokunciphisa isidingo sokukhishwa kwezinto zokusetshenziswa.

2.Izindleko - ukusebenza kahleUkusebenzisa i-TPU esetshenzisiwe kungaba ngcono kakhulu kunokusebenzisa i-TPU engeyona i-virgin. Njengoba inqubo yokuvuselela isebenzisa izinto ezikhona, ivame ukudinga amandla amancane kanye nezinsizakusebenza ezimbalwa uma kuqhathaniswa nokukhiqiza i-TPU kusukela ekuqaleni, okuholela ezindlekweni zokukhiqiza eziphansi.

3.Izakhiwo Ezinhle Zemishini: I-TPU ephinde yasetshenziswa ingagcina izici eziningi ezinhle kakhulu zemishini ye-TPU engeyona i-virgin, njengokuqina okuphezulu kokuthamba, ukuguquguquka okuhle, kanye nokumelana okuhle kokuguguleka. Lezi zakhiwo ziyenza ifaneleke ezinhlelweni eziningi lapho kudingeka khona ukuqina nokusebenza.

4.Ukumelana namakhemikhali: Inokumelana okuhle namakhemikhali ahlukahlukene, uwoyela, kanye nezinyibilikisi. Lesi sici siqinisekisa ukuthi i-TPU ephinde yasetshenziswa ingagcina ubuqotho bayo kanye nokusebenza kwayo ezindaweni ezinzima futhi lapho ivezwa ezintweni ezahlukene, yandisa ububanzi bokusetshenziswa kwayo.

5.Ukuzinza Kokushisa: I-TPU ephinde yasetshenziswa ibonisa ukuzinza okuhle kokushisa, okusho ukuthi ingamelana nobubanzi obuthile bamazinga okushisa ngaphandle kwezinguquko ezibalulekile ezimpahleni zayo zomzimba nezomshini. Lokhu kuvumela ukuthi isetshenziswe ezisetshenziswayo lapho kudingeka khona ukumelana nokushisa.

6.Ukuguquguquka: Njenge-TPU engeyona i-virgin, i-TPU ephinde yasetshenziswa iguquguquka kakhulu futhi ingacutshungulwa ibe izinhlobo ezahlukene kanye nemikhiqizo ngokusebenzisa amasu ahlukahlukene okukhiqiza, njengokubumba nge-injection, i-extrusion, kanye nokubumba nge-blow. Ingenziwa ngokwezifiso ukuze ihlangabezane nezidingo ezithile zezimboni ezahlukene kanye nezinhlelo zokusebenza.

7.I-Carbon Footprint Encishisiwe: Ukusetshenziswa kwe-TPU ephinde yasetshenziswa kusiza ukunciphisa umthelela wekhabhoni ohlotshaniswa nokukhiqizwa kwe-TPU. Ngokusebenzisa kabusha nokusebenzisa kabusha izinto, ukukhishwa kwamagesi okushisa ngesikhathi senqubo yokukhiqiza kuyancishiswa, okuzuzisayo ekulweni nokushintsha kwesimo sezulu.

Isicelo

Izicelo: Imboni Yezicathulo,Imboni Yezimoto,Imboni Yokupakisha,Imboni Yezindwangu,Insimu Yezokwelapha,Izicelo Zezimboni, Ukuphrinta kwe-3D

Amapharamitha

Amanani angenhla aboniswa njengamanani ajwayelekile futhi akufanele asetshenziswe njengemininingwane.

| Ibanga | Okuqondile Amandla adonsela phansi | Ubulukhuni | Ukuthamba Amandla | Okokugcina Ukwelulwa | I-Modulus | Izinyembezi Amandla |

| 单位 | g/cm3 | Ulwandle A/D | I-MPa | % | I-MPa | I-KN/mm |

| R85 | 1.2 | 87 | 26 | 600 | 7 | 95 |

| R90 | 1.2 | 93 | 28 | 550 | 9 | 100 |

| L85 | 1.17 | 87 | 20 | 400 | 5 | 80 |

| L90 | 1.18 | 93 | 20 | 500 | 6 | 85 |

Iphakheji

25KG/isikhwama, 1000KG/iphalethi noma 1500KG/iphalethi, icutshungulweipulasitikiiphalethi

Ukuphatha Nokugcina Isitoreji

1. Gwema ukuphefumula umusi kanye nomhwamuko wokucubungula ukushisa

2. Imishini yokuphatha imishini ingabangela ukwakheka kothuli. Gwema ukuphefumula uthuli.

3. Sebenzisa amasu afanele okusekela phansi lapho uphatha lo mkhiqizo ukuze ugweme ukushaja kwe-electrostatic

4. Ama-pellet phansi angase ashelele futhi abangele ukuwa

Izincomo zokugcina: Ukuze ugcine ikhwalithi yomkhiqizo, gcina umkhiqizo endaweni epholile neyomile. Gcina esitsheni esivalwe kahle.

Izitifiketi